Features

Sailent Features

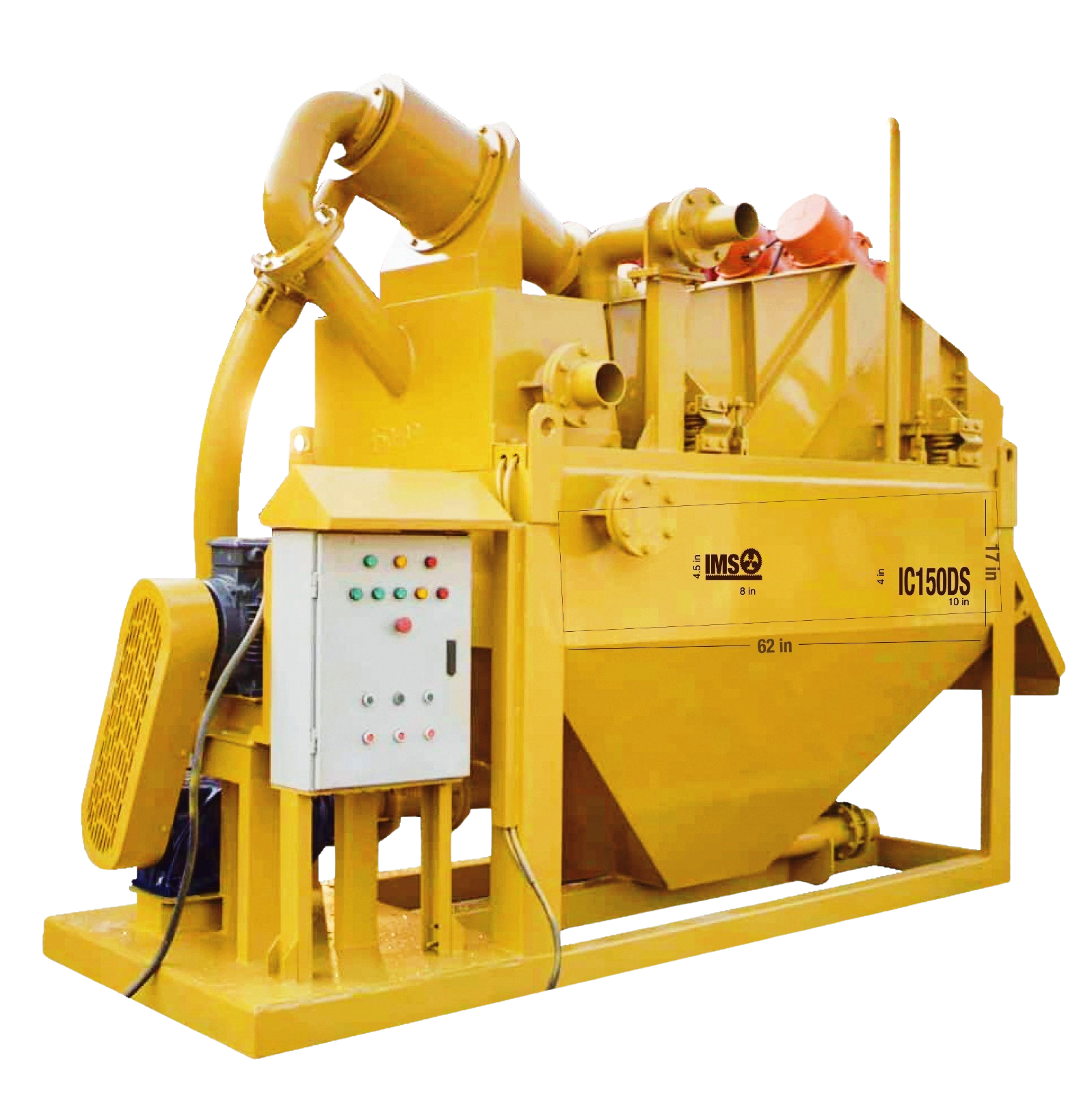

The Icon Machinery Solution, is manufacturing based company. The inaugurating machine include as follows.......

1. CLC Machine

2. Desander

3. Batching Plant

4. Drilling Bucket

Screw conveyor for fly ash

Inventory Management System

Admixture weighting system

Output - 30 cum/hr

Aggregate storing - 3-inline bins

Aggregate charging - Conveyor belt

Bin storage capacity - 15 cum

Cement-feeds - Screw conveyor

Admixture weighing system - Optional

Mixer - Twin Shaft

Maximum size of aggregate - 40mm

Bin gate operation - Pneumatic

Control system - PLC

Power Rating - 35.5 kw

Weight approx - 8.5 ton

Innovative method for constructing cast-in-place non-load bearing walls using Cellular Lightweight Concrete, without bricks & without blocks.

Approving code

American Concrete Institute, ACI 523.1R-06

Indian Standards, IS 2185-4 (2008)

Material

Cellular Lightweight Concrete, CLC

Ingredients

Cement, river sand, water and foaming.

Method

Ingredients are mixed in ribbon type mixture & poured in form and cured under water spray.

▪ Reduces dead weight of structures.

▪ Labor & mortar for stacking blocks not required.

▪ Smooth surface finish, plaster may not be needed.

▪ Reduces sound and heat conduction.

▪ Handling loss is less.

▪ No cutting and transportation waist.

▪ Reduces transportation cost significantly.

Desander separates sand particles from bentonite slurry. It is essential device for handling

+8801777775680

info@imsbangladesh.com

Level 06, Sel Trident Tower

57, Purana Paltan Line, VIP road Dhaka-1000

Saturday to Thursday

Office time: 10 AM - 5:30 PM